@stu1811 - The middle makes no difference, same issue.

Well damn! If it were me, I’d be changing the box type to a metal one before I started messing with the hole on the switch. If you make that hole much wider, odds are good the head of the screw goes through it.

Even without the grounding strap there, the plastic where that screw hole is sits much lower than a standard metal box. Then you add the thickness of the strap and what appears to be a gap between the plastic and the strap and I can see how this will cause issues for just about any type of smart switch.

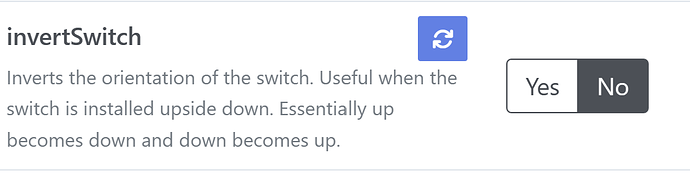

One other option, and it may not be ideal… The switches have a setting to invert them. You COULD install the switch upside down and then invert it through the settings. Your LED bar would end up on the other side, and my OCD would make me do this for every switch in the house, but it may be your only solution without getting in there and changing out all those plastic boxes.

What about installing the switch upside down and using the invert parameter? Yes I understand it won’t look like the others but it’s an option.

Yeah, these options are far beyond time I’m willing to invest in making these switches work. Guess I may just try and return them at this point and try and find something else. The main reason I bought these was for the smart switch mode to control smart lights.

I appreciate the help everyone!

I agree, switching out to metal boxes is a lot of work. But flipping it upside down takes literally 2s and may just solve your problem.

EDIT: Just to clarify, by flipping it we mean place the ground screw of the switch on the bottom. Your LED bar will be on the side of the Lutron switch. Then you just go into the settings and say the switch is inverted so “Up” will still turn on the lights.

Inovelli has sold thousands of switches to Canadian users. @andrew_t is certainly not the only person in the country that has a plastic box. To my knowledge, this has never come up before. Makes me wonder if there is something obvious that’s being missed.

If you are Canadian and have plastic boxes with the grounding straps, this would be a good time to explain if you have had alignment issues . . .

True, it does seem like it could work to invert them. I’ll look into how much effort it will be on the programming and automation side, which needs to be factored in as well.

However, they do look odd and I think it will bother me.

I had a few plastic boxes and didn’t have any fit issues. I can’t say they are exactly the same though, I’d have to take a switch out to have a look. In the end I did switch all my remaining switches out with Blues for the uniform look, but they lined up fine next to the Legrand switches in there prior.

I don’t know which platform you’re using, but the “programming” to invert them should be similar between all of them.

You just have to click on yes or no. Once you click yes, everything else will just work as normal. And once you get it in there with the other switches beside it and the faceplate on, it will look pretty normal too. Right now you’re seeing all the writing upside down which tells your brain it must be wrong. LOL But that option is there because many people choose to install them this way, not out of necessity like you but because it’s their preference.

I’m using them with home assistant and Zigbee2MQTT. Your right it could be my brain just needs to get used to the look. I guess at this point I might as well try inverting the one for a bit and see how it works before giving up completely.

I guarantee if you flip it and then show it to anybody who’s never seen it with the LED on the other side, they will have no idea it’s upside down.

Probably. Seems like this is the setting I want to change then: Inovelli VZM31-SN control via MQTT | Zigbee2MQTT.

That’s the one!

The screenshot I took was from Zigbee2MQTT. So once you’ve got it joined to your network you don’t have get into sending MQTT commands to change it, just go under the exposes tab in Z2M and click yes. I believe you’ll also have an entity that you can use in Home Assistant to change it as well.

Ok cool. I have it paired already, so seems pretty easy to change once I turn the breaker back on. Will try it out and see. Thanks!

This was an interesting thread to read through and @andrew_t – very sorry you’ve experienced this. I have never seen these before and am surprised this has never come up as we’ve sold a lot in Canada.

It might explain why Jasco redesigned their switch to put the ground screw to the left (instead of center) and something I guess we should look into.

–

To my friends up north, if this is being sold at big box stores, why has no one else ever experienced this? I just looked at our Gen 2’s and Gen 1’s and the ground screw design hasn’t changed (outside of us adding an additional terminal hole).

Is this a new design and/or requirement?

–

@andrew_t – couple of questions for you so I can revisit the design:

- Is the metal tab catching on the ground screw? In other words, if we made the ground screw flush or even recessed, would you still have this issue?

- Can you post the back of the Lutron switch? Or if it’s too much of a pain, just let me know the model number and I can look at it.

I’ve been meaning to move the ground screw to one of the sides as I’ve heard complaints over the years that the screw that goes into the gang-box gets in the way of the ground screw sometimes, but this would definitely put it over the edge if we can’t get this working with Canadian gang-boxes.

Don’t take this as advice. But is that metal tab even necessary? The switch is already bonded to ground with the wire.

Edit: just to clarify, that tabs purpose is to bond the metal components of switches that don’t have a factory ground terminal. The wire you are attaching to the switch is doing the same task as that metal tab.

From my understanding, up here the screw on the device itself is considered a “backup” ground in the event the primary bond through the mounting screw should fail. In 2021 they made the ground on the device optional but I don’t think it’s a “one or the other” type scenario. It’s either both, or just the mounting screw.

Fair enough. I’ve been out of the residential wiring world for over 10years now and have not stayed current with the relevant codes.

I’ll look into the codes tomorrow when I have access to the 2021 CEC as this has me interested.

For anyone interested, 10-614 is the relevant rule. I’m not going to provide my interpretation of the rule on a public forum. But it’s worth noting that appendix B does leave some room for this to go either way.

Ultimately I think it comes down to the manufacturer requirements.

@Eric_Inovelli - Thanks for following up and providing clarity. I’ll try my best to answer your questions.

Is the metal tab catching on the ground screw? In other words, if we made the ground screw flush or even recessed, would you still have this issue?

It’s hard to say for sure. Moving the ground screw to the side or making it flush would help, but it definitely would still be a very tight squeeze if it did fit (which I can’t guarantee). If the gang box were installed on the other side of the stud (flipped), then there wouldn’t be any alignment issues, except if you wanted to install the switch inverted on purpose. The 2 other gang boxes I want to install this switch in are also installed the same way, so my only option at the moment is to install the switch inverted as suggested.

Can you post the back of the Lutron switch? Or if it’s too much of a pain, just let me know the model number and I can look at it.

The Lutron switch is a PD-6WCL. The dimensions should be listed in the technical specs. The Lutron switch back size is very close in width, height, and depth. However, the the top does not extend quite as high. The difference is maybe about 2-4mm. I can’t be certain that moving the ground screw would work alone, but it definitely would if the top was lower by maybe 2mm or. This would likely make the difference needed to work in these types of gang boxes.